Adaptability

How an Engineering Organization Achieved

Bubble Up Transformation

Background

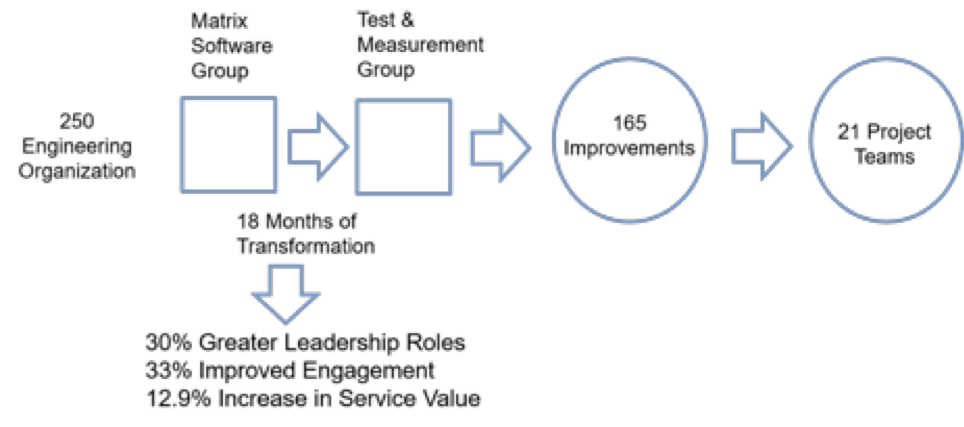

An engineering organization of a high-tech Fortune 500 company experienced a high degree of stress due to rapid scaling and very tight produce cycle times. Engineering executives of a 270 person software division were worried about declining engagement and increased turnover. They selected FrameWork in order to achieve the following objectives: (1) Clarify the work being performed per person as related to individual talent; and (2) how to effect changes that would eliminate 5% or more lower value or wasted work.

One engineering group (group 1) was located in Silicon Valley representing a matrix organization producing embedded software. The second organization (group 2) was located in Southern California and provided test and system integration. It represent the “customer” of the first organization. The two groups’ culture and management style were significantly different – the second being much more top down. Both groups were frustrated over inefficiencies and wanted to see changes that would enhance the use of their talent.

Getting Started

The process began with Group 1. CollabWorks and the engineering managers agreed on roles, support for the process, and the data used to define the services of the group. Step 1 of the process began with an overview of the group objectives, FrameWork process, and encouraging support from management to be open and candid about issues and ideas for improvement. All participants then completed self-assessments where their perceptions of their work and use of talent is captured. Afterwards the participants discussed their collective results, including dozens of identified issues and improvement ideas. The lowest assessment score was related to Group Characteristics – Work where 47% of the responses were somewhat negative to very negative. Time wasted in meetings was a major issue. Many felt their talent was underutilized. The managers co-participated and encouraged an open candid dialog. The energy in the room went way up as engineers began to realize their input mattered.

Positive Energy Went Up When Their Feedback Mattered

Following the self-assessment, Group 1 continued to Step 2, a facilitated session where all participants:

(1) Defined typically 6-10 services adding up to 100% of their work; then they identified the customers receiving value per service, the relative service value, and objectives when needed to improve their service(s);

(2) Created a 6-month transformation plan describing specific changes in service(s) in order to meet objectives, address personal desires, and increase service value.

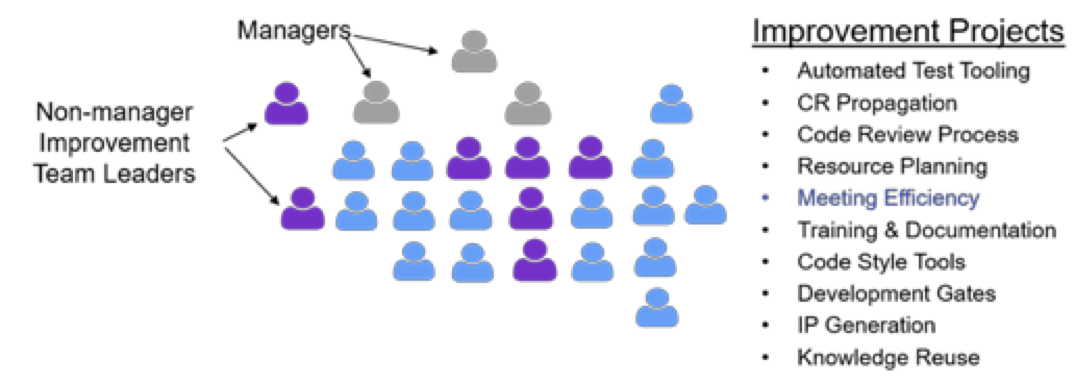

Once the service profiles and transformation plans were completed, the group selected from a list of 165 potential improvements. 10 projects were selected to address the most important issues to improve both individual and group performance. Team leaders and co-leaders where selected per improvement project. They then formed teams from within the group, created project plans and presented (many for the first time) to senior executives. All 10 projects were approved.

70% of Improvement Team Leaders were Non-managers

All project teams reported periodic progress to their managers. Some projects were completed within 3 months, others in 9 months. The initiatives and deliverables were driven by the teams themselves and not from the top down. The results were remarkable. For example, an automated test tool project reduced repetitive work by 80% and cycle time by 20%. The IP team met at lunch every other week, refined their process, and have since produced 4 times the patent applications. Meeting of all types were improved in both process and reduced interruptions. This led to increases in higher value work such as architecture design. Mary’s Team on Training and documentation produced an overall measured productivity improvement of 3%.

Group 2 was initiated 9 months after Group 1 and benefitted from Group 1’s experience. While the function and management culture was more process and control driven, the personal and group improvements opportunities were similar to Group 1. Group 2 identified 11 project teams who in turn defined and received executive approval for each project. The process allowed under utilized engineers to implement improvements that enhanced the use of their talent.

Group 1 and 2 Produced Similar Results with Different Cultures

Summary

Allowing individuals to express their needs and to act on their ideas for both personal and group improvements produced business value and significantly improved engagement. The quantitative nature of FrameWork provided a sound basis for investing in improvements that are often known but not addressed. The bubble up process of identifying and producing improvements worked and engaged all levels of the organization. Engineers gained valuable experience in assuming leadership roles and frankly stunned seniors executives with their initiatives.

The quantification of services performed as percent FTE demonstrated that too little time was being given to quality coding and much of issue could be addressed by minimizing disruptions such as low or no value meetings and communication. One important discovery was the top talent was performing only 35% top talent work. The transformation process produced a reduction in waste of 7.6% and an increase in top talent services by 15%.

The FrameWork assessment was repeated after 15 months and the overall engagement score improved by 33%. The main attributes of this engagement improvement included: (1) Direct correlation in the reduction of wasted time – particularly meetings; (2) Participation and leadership of successful improvement teams; and (3) Increase in the value of services by 12.9%. The estimated 2-year benefit to Engineering was $3M and the time to breakeven on FrameWork costs was 2 months.